NMP Substitution

CAS 872-50-4

Synonyms N.Méthyl.2.Pyrrolidone

M Pyrol

1-Méthylazaccyclopentan-2-One

NMP, like NEP (N.Ethyl.2.Pyrrolidone) CAS 2687-91-4, has been classified by the CLP Regulation CE 1272/2008 / GHS CMR Reprotoxic.

H 360 D May cause harm to the foetus

H 319 Causes severe eye irritation

H 315 Causes skin irritation.

CLEANING AND DISSOLVING SOLVENT

PE, PU RESINS, EPOXIES, BIS GMA

GLUES, INCLUDING POLYMERISED GLUES,

CYANOACRYLATES, METHACRYLATES

POLYESTERS and NITROCELLULOSES

NOT CLASSIFIED AS FLAMMABLE

HIGH SETTLING POWER

Recoverable Reusable

RECYCLABLE BY DISTILLATION

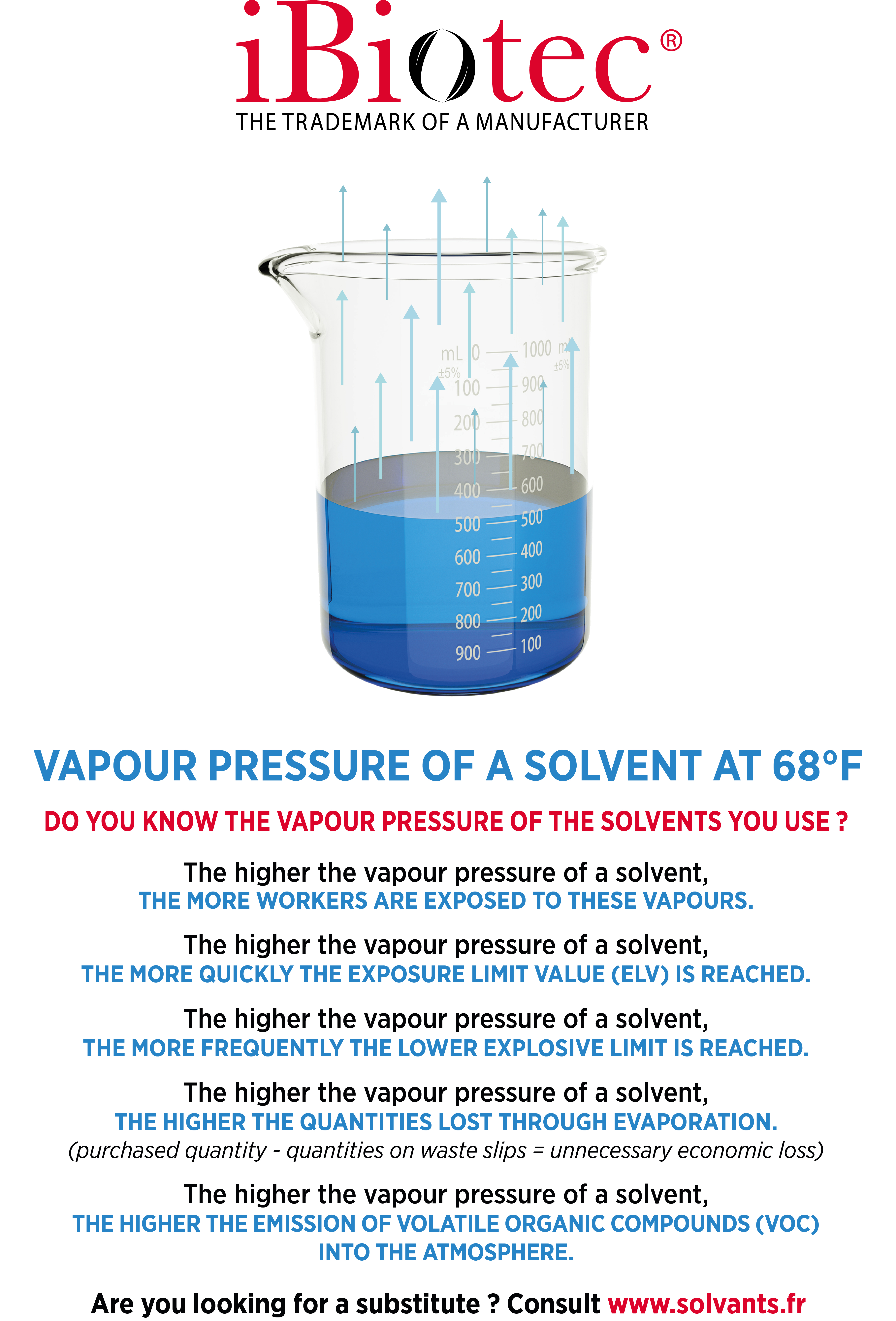

LOW VAPOUR PRESSURE

Decrease in Consumption

INFINITY is part of an ongoing process to reduce danger pictograms.

INFINITY is a powerful solvent, remover and stripping agent for varnishes, paints, polymers, copolymers and composites, as well as for combustion engine residues.

It is also an excellent solvent for cured anaerobic glues and resins.

Its action time is greatly accelerated in hot-dip galvanizing.

TYPICAL PHYSICAL AND CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES RG 30 |

VALUES INFINITY |

UNITS |

|

Appearance |

Visual |

Clear |

Liquid |

- |

|

Colour |

Visual |

Colourless |

Colourless |

- |

|

Odour |

Olfactory |

Properties |

Odourless |

- |

|

Density at 77°F |

NF EN ISO 12185 |

0.889 |

1110 |

kg/m3 |

|

Refractive index |

ISO 5661 |

1.3980 |

1.4300 |

- |

|

Freezing point |

ISO 3016 |

-58 |

-40 |

°F |

|

Distillation range |

ISO 3405 |

246,2-258,8 |

374-401 |

°F |

|

Vapour pressure at 68°F |

ASTM D 5188 EN 13016.1.2.3 |

1.2 |

2.70 |

kPa |

|

Solubility in water |

- |

0.01 |

Partial |

% |

|

Kinematic viscosity at 104°F |

NF EN 3104 |

0.86 |

1.5 |

mm²/s |

|

Acid value |

EN 14104 |

<1 |

0 |

mg(KOH)/g |

|

Iodine value |

NF EN 14111 |

0 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

<0.1 |

% |

|

|

Residue after evaporation |

NF T 30-084 |

0 |

0 |

% |

|

PERFORMANCE CHARACTERISTICS |

||||

|

PROPERTIES |

STANDARDS |

VALUES RG 30 |

VALUES INFINITY |

UNITS |

|

KB index |

ASTM D 1133 |

>150 |

nm |

- |

|

Evaporation rate |

- |

4.30 |

>6 |

minutes |

|

Surface tension at 68°F |

ISO 6295 |

27.5 |

35.5 |

Dynes/cm |

|

Copper blade corrosion 100h at 104°F |

ISO 2160 |

1a |

1a |

Rating |

|

FIRE SAFETY PROPERTIES |

||||

|

PROPERTIES |

STANDARDS |

VALUES RG 30 |

VALUES INFINITY |

UNITS |

|

Flash point (closed cup) |

NF EN 22719 |

86 |

95 |

°F |

|

Self-ignition point |

ASTM E 659 |

>446 |

>482 |

°F |

|

Lower explosive limit |

NF EN 1839 |

1.2 |

0.9 |

% (by volume) |

|

Upper explosive limit |

NF EN 1839 |

13.7 |

8.7 |

% (by volume) |

|

TOXICOLOGICAL PROPERTIES |

||||

|

PROPERTIES |

STANDARDS |

VALUES RG 30 |

VALUES INFINITY |

UNITS |

|

CMR, irritating and corrosive substance content |

CLP Regulation |

0 |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

0 |

% |

|

ENVIRONMENTAL PROPERTIES |

||||

|

PROPERTIES |

STANDARDS |

VALUES RG 30 |

VALUES INFINITY |

UNITS |

|

Water endangering |

WGK Germany |

1 non-water endangering |

|

class |

|

Primary biodegradability CEC 21 days at 77°F |

L 33 T82 |

>70 |

>70 |

% |

|

Readily biodegradable OECD 301 A over 28 days Disappearance of the COD |

ISO 7827 |

>70 |

>70 |

% |

|

Easy and ultimate biodegradability OECD 301 D over 28 days |

Modified MITI |

72 |

|

|

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.